Over the summer while dining at Hotel Congress, Del Hendrixson Jr. noticed signs set out about straws.

тWe only serve straws upon request,т read the signs, which are part of an environmental movement to reduce plastic waste.

Hendrixson runs a printing business т designing and printing artwork for businesses to infuse onto glass products, such as jewelry and beer mugs.

But when he sat at Hotel Congress, he realized he could take his business to the next level. And although he could тsee the writing on the wallт months prior, Hendrixson decided to dip his toes into the glass-straw business.

The concept of glass straws isnтt a new one, but Hendrixson says his straws are different.

People are also reading…

тI saw so many people starting to make glass straws, but they couldnтt put logos on them,т Hendrixson says.

тWe can make logos. So, we just said one day, тWhy donтt we make glass straws?тт

Each of Hendrixsonтs straws, which are made in a warehouse near Armory Park, feature detailed designs.

Some say things like тУлшжжБВЅ cares.т Others sport business logos.

And while it doesnтt take a whole lot of time to make the straws in bulk, the individual process can be a tedious one.

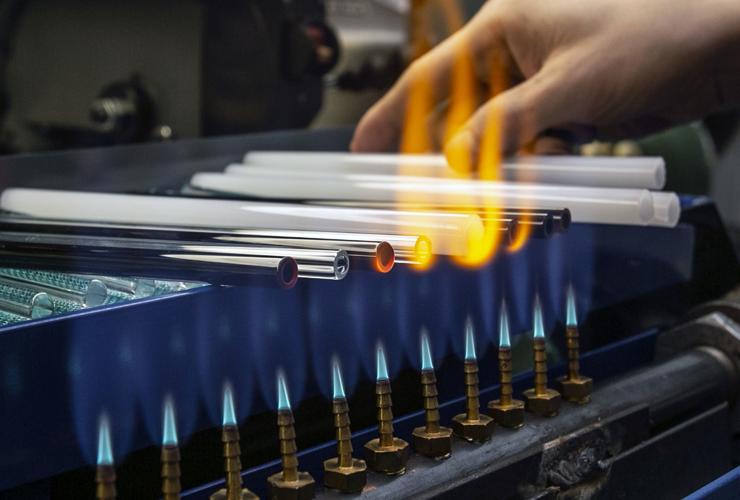

It takes Hendrixsonтs team about two hours to complete each straw, which includes cutting long glass tubes, flame-polishing the ends, then printing the designs using pigment and water slide paper.

With the help of a little water, the designs are infused onto the straws, which then go into a kiln at 1,100 degrees. Once theyтre cooled, theyтre finished.

Although the process includes many detailed steps, Hendrixson says his team can make around 500 straws in that two-hour time frame.

Hendrixson says heтs happy he gets to do something that allows him to be creative т especially when it also helps the environment and those working in animal conservation.

тIтm into prevention т preventing people from committing crimes, people from hurting each other,т Hendrixson says. тSo I thought this was also a perfect opportunity to prevent something. Why shouldnтt we, as people, do something to help sea animals?т

He also says that as straw orders increase, he plans to work with the community to provide outreach opportunities.

тEvery single level of this straw (business) is helping someone,т he says.

Hendrixson says heтs made straws for several local businesses, including Hotel Congress, Maynards Market & Kitchen and Magpies Gourmet Pizza.

Since summer, Fourth Avenueтs Pop Cycle, which is known for its up-cycled products, has carried the straws.

Store Manager Libby Tobey says customers love them.

тWith our store and our motto, we really liked the product,т she says. тWeтve enjoyed carrying them т and that itтs a local business and theyтre eco-friendly.т

For more information, head to

Photos: УлшжжБВЅ business breaks into glass straw production

Glass straws

Glass straws are manufactured at УлшжжБВЅ-based . The straws, made from borosilicate glass and printed with borosilicate infused decals, are produced as alternatives to plastic straws.

Glass straws

Glass straws manufactured at УлшжжБВЅ-based . The straws, made from borosilicate glass and printed with borosilicate infused decals, are produced as alternatives to plastic straws.

Glass straws

Ricky Segura, project manager at УлшжжБВЅ-based , marks borosilicate glass tubes to be scored and cut to size at a small warehouse in УлшжжБВЅ, AZ. on January 9, 2019. The straws, made from borosilicate glass and printed with borosilicate painted decals, are offered to companies as alternatives to plastic straws.

Glass straws

Xavier Mungia cuts decals printed with borosilicate paint at УлшжжБВЅ-based , in УлшжжБВЅ, AZ on January 9, 2019.

Glass straws

Borosilicate printed decals are hand set on each straw and then fired in a custom-made belt-driven kiln at УлшжжБВЅ-based in УлшжжБВЅ, AZ. The borosilicate printed decals fuse to the borosilicate straw making the printing essentially impervious to scratching or removal.

Glass straws

Borosilicate paint is mixed in custom colors to exacting standards at УлшжжБВЅ-based . The borosilicate printed decals fuse to the borosilicate straw making the printing essentially impervious to scratching or removal.

Glass straws

Senior pressman Cisco Valencia applies a blue borosilicate paint onto a printing plate to be printed onto waterslide decal paper at УлшжжБВЅ-based in УлшжжБВЅ, AZ on January 9, 2019.

Glass straws

Sheets of blue waterslide decals printed with borosilicate paint come off the press individually at УлшжжБВЅ-based in УлшжжБВЅ, AZ on January 9, 2019.

Glass straws

Ricky Segura, left, and Cisco Valencia, from left, make sheets of blue borosilicate waterslide decals one at a time at in УлшжжБВЅ, AZ on January 9, 2019. The sheets are air dried and cured on a drying rack.

Glass straws

Del Hendrixson, Cisco Valencia and Ricky Segura, from left, make sheets of blue borosilicate waterslide decals one at a time at in УлшжжБВЅ, AZ on January 9, 2019.

Glass straws

Del Hendrixson explains the printing process he used on a project for boxer Mike Tyson using 24K gold based paint at in УлшжжБВЅ, AZ.

Glass straws

Glass straws pass over a set of flames on a polisher designed by Del Hendrixson to smooth the sharp raw ends of the scored glass straws at in УлшжжБВЅ, AZ on January 9, 2019. A properly tuned propane flame is hot enough to melt the glass to a smooth, rounded end.

Glass straws

Del Hendrixson with a printed glass straw at in УлшжжБВЅ, AZ on January 9, 2019. Prior to founding , Hendrixson used his printing business to print designs for glass products, such as beer mugs and jewelry.